Following the driveline back is an HKS 10 lb. lightweight flywheel and heavy duty (820kg) pressure plate (so far I have been having problems getting the clutch to disengage properly, so the clutch will be replaced with another brand sometime soon). The transmission is a '82 non-turbo unit, which I chose because of the better ratios (after much researching I found it had the same 1st - 4th gear ratio's as the Nissan Comp 'Close Ratio Overdrive' transmission), a better 0.754 overdrive and a 'reverse lockout' to keep you from grinding gears when shifting from 5th to 4th in a hurry. I talked to Ron Johnson from Nissan Motorsports regarding the strength of this unit, and he stated that the tranny could take up to 500 hp, but it was shock that would kill it. He said it was basically the same tranny they used in the 600 hp IMSA Z-cars in the early '80's. I have always hated the feel and the cantankerous shifting of the Borg-Warner unit used in the '83 ZX turbo (plus it has sh*tty ratio's), so I'm going to avoid resorting to it if at all possible.

The driveshaft is a 260Z unit which is the same size as the 280Z unit but has replaceable u-joints. Although I haven't had any problems yet, I plan to have a custom driveshaft built up in the future as quality u-joints are not available for the stock shaft. The custom unit will consist of a lightweight aluminum shaft and a Nissan P/U truck flange which will fit the R200 and has a MUCH bigger u-joint carrier that a high quality Spicer u-joint will fit. It should be a pretty much indestructible piece.

The diff is a 3.7 Limited-Slip R200 unit out of Daltech Racing's 300ZX IMSA race car (they were located across the parking lot from Cartech ). The only mods necessary (besides replacing the mustache bar) were to replace the vented rear cover with a non-vented one out of an earlier Z and have the driveshaft end yoke replaced with a size matching the 300ZX diff. Actually, the LSD can be found in all '88-'89 300ZX Turbo's, and they will bolt in with the above mods.

The halfshafts were lubed, inspected and balanced. The original u-joints are holding up for now, but Spicer joints are available and will probably be installed in the future.

Fuel is supplied by a high pressure Bosch pump from a Turbo Porsche that is mounted to the body just ahead of the rear axle using a 280Z bracket (it's the same size pump as the stock Nissan FI Z-cars). A 1/2" aluminum fuel line is run from the pump to the engine compartment where it connects to a -8 Aeroquip line, to an Essex Aircraft Quality 10 micron fuel filter with replaceable element. The -8 line continues to a custom large bore fuel rail (the use of the stock rail is not recommended due to the possible restrictive nature of the small tubing) and to special Bosch high flow fuel injectors. A stock ZX Turbo fuel pressure regulator is plumbed in at the end of the new rail. A -6 Aeroquip line ties in from the regulator output to the original fuel supply line, which is now used as the return line.

Fuel management is handled by an ACCEL DFI Digital Fuel Injection system. It is one of the more popular (and reliable) aftermarket FI systems on the market today. It is a totally programmable fuel injection system that can be programmed with a laptop computer. A future article will detail the workings, programming and use of the DFI unit, as well as some comparisons to the other units available on the market.

Ignition is handled by an early 280ZX distributor and module that outputs a signal to a J&S Safeguard Knock Sensor. The J&S is a microprocessor-based individual cylinder knock control unit with advanced discriminatory circuits to ignore engine noise and focus on engine knock. It has a built in rev-limiter and an optional LED display. The control box is mounted inside on the drivers kick panel. The newer DFI systems actually have built-in ignition control with detonation sensor. I am tempted to upgrade to the newer units, but I would hate to loose the individual cylinder control and the display (so I can monitor what is going on). The coil is a stock '82 ZX unit - it just happened to be sitting around.

To monitor everything I have installed a Cartech boost gauge; the J&S ignition retard-air/fuel meter; a super-trick GReddy EGT (Exhaust Gas Temp) gauge with programmable warning light and memory recall; Auto-Avionics temp gauges with programmable warning light for the engine oil, transmission oil, diff oil and intercooler outlet temp. Future additions (as the budget will allow - the GReddy gauges are about $250 a pop!?) will include GReddy water temp and oil pressure gauges.

Right now I am trying to keep the boost around 10-12psi, although it will easily and quickly zip up to 14-15psi.

The next couple of articles will cover specific areas such as the DFI system, fender flaring and wheel offset, brake upgrades, sound insulation (there is currently 50lbs of lightweight aircraft sound insulation in the car), 240Z wiring (I rewired the overtaxed stock setup using Military Spec aircraft circuit breakers from a Learjet), and any other weird stuff I did.

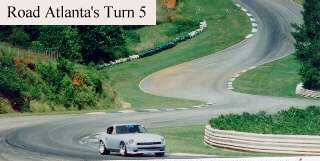

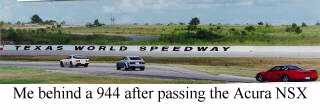

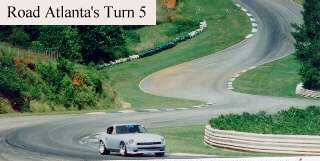

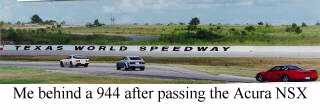

I'll finish with some musings from last summer: 140MPH and accelerating @ 12psi of boost and half throttle on the back straight of Road Atlanta, then suddenly thinking "This is the second time I have driven the car in 5 years, I wonder how well the brakes work!!??", and backing off. [To Dave Olson's (my navigator and overly trusting friend) credit he didn't say a word the whole time around the track - although I always thought that 'screeching' noise was the tires...thinking about it though, Dave a little hoarse that evening!?]